|

|

This article appeared in EAA Sport Aviation in August 2006

MANOMETER or HOW FAST ARE WE GOING?

Have you ever wondered just how accurate your airspeed indicator is? Does your

pitot system have more holes in it than a slice of Swiss cheese? Can you

pressure test a fuel tank, without worrying about putting to much pressure in

it. Your answer lies in a Manometer. Have you ever wondered just how accurate your airspeed indicator is? Does your

pitot system have more holes in it than a slice of Swiss cheese? Can you

pressure test a fuel tank, without worrying about putting to much pressure in

it. Your answer lies in a Manometer.

A Manometer gives you

the ability to accurately measure very small pressures. The theory behind a

Manometer is simple, how much pressure does it take to push a column of water

straight up, through a tube.

We use a simple form of a manometer almost every day of our lives. Every time

we sip a drink through a soda straw, we use differential air pressure to push a

liquid up the straw. We’re going to do exactly the same thing here, except our

straw is going to be much larger, and it has a gauge to indicate exactly how

far the liquid moves.

THE SCALE:

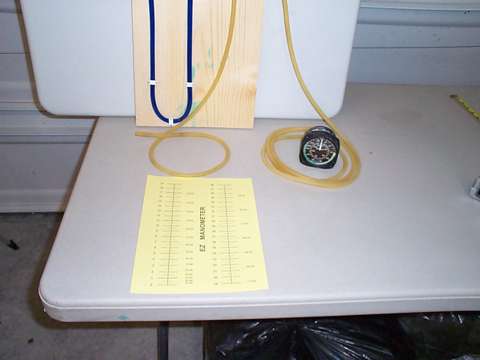

The Scale can be printed from the file

"Manometer.PDF".

Print or copy the Pressure Scale sheet. Use a tape measure to verify that the

scale sheet didn’t shrink or expand in the printing process. The distance

between the 0 and 19 inch marks should be exactly 9 ½ inches, This is critical

for the accuracy of the Manometer.

Cut out the 0 – 19 inch

scale and slide it under the Left leg of the "U-Tube". The "0"

or "ZERO LEVEL" should be approximately in the center of the U-tube. Cut out the 0 – 19 inch

scale and slide it under the Left leg of the "U-Tube". The "0"

or "ZERO LEVEL" should be approximately in the center of the U-tube.

If you plan to use the Manometer to measure over 19 inches, then cut out the 19

– 38 scale. Tape it so the 19 is directly over the 19 on the 0 – 19 scale. Use

a tape measure to verify that the full scale, 0 – 38, reads exactly 19 inches.

The scale has two sets of numbers, Inches on the left, and Knots on the right.

Upon initial inspection, you may think that the scale is wrong, because each ½

inch is labeled as an Inch. The following demonstration will answer this

question, plus provide you with a good idea of how small a pressure the

Manometer is capable of measuring.

DEMONSTRATION: Fill the "U" tube to about the ½ point with water.

Blow very gently into the one side of the "U" tube. As the pressure

that your applying pushes the water level down on one side, the water level on

the other side of the tube goes up an equal amount. If we measured the

difference between the two sides, this is pressure that we’re exerting, in

"inches of water".

CONSTRUCTION:

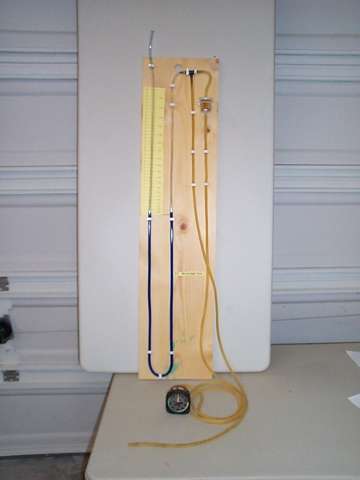

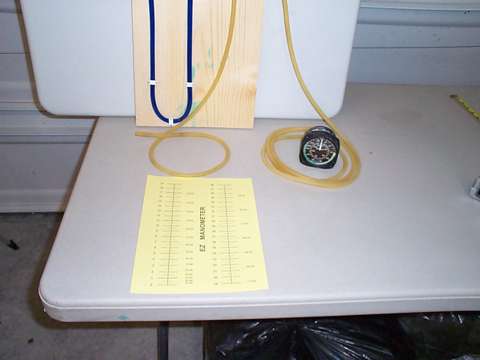

Follow the general layout shown in the diagram.

Most, if not all the parts can be purchased at a hardware or department store.

Look in the plumbing and automotive departments.

| |

10 ft. of 3/8 inch Clear Vinyl tubing for the "U" tube |

| |

15 ft. of 3/8 inch "Surgical" tubing for connecting to pitot systems |

| |

1 "T" fittings for 3/8 inch tube |

| |

FRAM G2 Gasoline Filter |

| |

1 x 10 pine board 48 inches long |

| |

Electrical staples for Romex wire. For securing the tube to the board |

| |

Golf "T"s |

The height of the "U" will depend on the pressure you want to

measure. If the maximum pressure is 19 inches, then make each leg of the

"U-Tube" at least 25 inches. If the maximum pressure is 38 inches, then

make the legs at least 44 inches. This will give a 6 inch safety margin at the

maximum pressures.

When securing the "U-Tube" to the board, Pay particular attention to the

location of the staples. The spacing of the staples leaves enough room to allow the paper scale to be

inserted between the tube and the board on the left side. The scale paper may also

need to slide up and down to adjust the ZERO LEVEL

DO NOT omit the FRAM filter. This filter does two things. 1) It reduces the

risk of accidentally getting water or other contaminants into the pitot system

during testing. 2) It acts as a baffle or shock absorber, thus reducing

pressure pulses going to the Pitot system.

The Pine board needs to be straight up and down. Drill a hole in the top and

hang it from a nail.

FILLING THE MANOMETER

Prepare 1 pint of water, preferably distilled, but soft tap water will work.

Mix food coloring into the water. Make it as dark as you can, this makes the

water level very easy to see. Mix 1 teaspoon of Dishwasher Softener into the

water. This reduces the surface tension of the water so it doesn’t stick to the

inside of the tube. Detergent will also work but you’ll have to allow the

bubbles to disperse before you can make any measurements. Prepare 1 pint of water, preferably distilled, but soft tap water will work.

Mix food coloring into the water. Make it as dark as you can, this makes the

water level very easy to see. Mix 1 teaspoon of Dishwasher Softener into the

water. This reduces the surface tension of the water so it doesn’t stick to the

inside of the tube. Detergent will also work but you’ll have to allow the

bubbles to disperse before you can make any measurements.

Stir the mixture, do not

shake. If you shake, you’ll be waiting for hours for all the bubbles to settle

Fill the "U" tube with the color water mixture. The exact level isn’t

critical. Fill so the level is about an inch above the middle staple, This will

be the ZERO ADJUST point

The Pine board needs to be straight up and down. Drill a hole in the top and

hang it from a nail.

When the bubbles settle and the two sides equalize, slide the paper scale up or

down so the ZERO ADJUST point on the scale is lined up with the water level.

VERIFY OPERATION and TEST FOR LEAKS

Pinch off the tube that goes to the Pitot system by using a Golf "T",

or some other plug.

Blow gently into the AIR SUPPLY hose. You’ll see the water level change. Get a

feel for how much pressure it takes to move the water. Blow gently into the AIR SUPPLY hose. You’ll see the water level change. Get a

feel for how much pressure it takes to move the water.

Practice pinching the AIR SUPPLY hose to hold a pressure. Release the pinch

just a little to generate a small leak. When testing an airspeed indicator, a

leak of approximately 1 inch of water every 5 seconds provides enough time to

compare the indicator with the Manometer scale.

Blow a pressure equal to about 120 knots, then pinch the AIR SUPPLY tube with

your fingers to hold the pressure. Put a Golf "T" into the end of the

AIR SUPPLY tube, then release your pinch. Once the level stabilizes, it should

remain at this level, indefinitely. This method is ideal for testing pitot

systems or fuel tanks for leaks.

PITOT LEAK TEST

Before getting serious

about calibrating airspeed indicators, make sure the system is not leaking.

Apply enough pressure to get about ½ of you red line airspeed, then pinch off

the AIR SUPPLY line. Once the Manometer stabilizes, the water level should not

change. If it does, you have a leak.

PITOT AIRSPEED CALIBRATION

NOTE – Airspeed indicators respond to pressure changes a lot fast than the

Manometer. When blowing into the AIR SUPPLY, do so gently so as not to cause

sudden, jerky movement on the Airspeed indicator. The FRAM G2 filter will

provide some protection, but the airspeed indicator can be permanently damaged

by sudden pressure changes. DO NOT peg the Airspeed needle.

Verify that the water level is at the ZERO LEVEL on the paper scale.

Gently blow into the AIR SUPPLY while watching the Airspeed Gauge. DO NOT peg

the airspeed indicator.

When the airspeed indicator is at its maximum reading, pinch the AIR SUPPLY

tube. Once the Manometer stabilizes, the water level should not change, there

should be no leaks.

Reduce the pinch on the AIR SUPPLY to generate a constant 1 inch every five

seconds. The Airspeed indicator should read the same as the airspeed on the

Manometer gauge. The Airspeed / Pressure table is provided for your convince.

You may need to gently tap on the airspeed indicator to get it to move, this is

normal.

LEAK CHECK FUEL TANK

Cap off all known ports in the fuel tank. Pressurize the tank in the same

manner as the PITOT LEAK TEST, but DO NOT EXCEED 100 knots. The tank should

hold pressure indefinitely.

TEST FOR VACUUM

The Manometer can just as easily test for Vacuum. Move the paper scale to the

right leg of the "U", and adjust the "0" ZERO ADJUST to the

water level. Instead of blowing into the AIR SUPPLY, sucking will generate a

small vacuum and "pull" the water column up.

Connect the Manometer to the Static system. While watching the Paper Scale,

Suck on the AIR SUPPLY tube to pull the water column to approximately 35

inches. Pinch off the AIR SUPPLY. Once the Manometer stabilizes, the water

level should not change, there should be no leaks.

35 inches of Water (vacuum) represents approximately 2,500 ft altitude

|

Knots |

In H2O |

PSI |

|

Knots |

In H2O |

PSI |

|

|

|

|

|

|

|

|

|

0 |

0.0000 |

0.0000 |

|

230 |

35.4855 |

1.2819 |

|

10 |

0.0180 |

0.0025 |

|

240 |

38.7350 |

1.3993 |

|

20 |

0.2583 |

0.0100 |

|

250 |

42.1476 |

1.5226 |

|

30 |

0.5846 |

0.0210 |

|

260 |

45.7234 |

1.6518 |

|

40 |

1.0469 |

0.0380 |

|

270 |

49.4486 |

1.7863 |

|

50 |

1.6315 |

0.0590 |

|

280 |

53.3507 |

1.9273 |

|

60 |

2.3521 |

0.0850 |

|

290 |

57.4159 |

2.0742 |

|

70 |

3.1590 |

0.1154 |

|

300 |

61.6442 |

2.2269 |

|

80 |

4.1740 |

0.1508 |

|

310 |

66.0493 |

2.3861 |

|

90 |

5.3024 |

0.1916 |

|

320 |

70.6312 |

2.5516 |

|

100 |

6.5397 |

0.2362 |

|

330 |

75.3898 |

2.7235 |

|

110 |

7.9265 |

0.2863 |

|

340 |

80.3387 |

2.9023 |

|

120 |

9.4492 |

0.3414 |

|

350 |

85.4644 |

3.0874 |

|

130 |

11.1079 |

0.4013 |

|

360 |

90.7804 |

3.2795 |

|

140 |

12.9026 |

0.4661 |

|

370 |

96.2868 |

3.4784 |

|

150 |

14.8332 |

0.5359 |

|

380 |

101.9972 |

3.6847 |

|

160 |

16.8998 |

0.6105 |

|

390 |

107.8979 |

3.8978 |

|

170 |

19.1159 |

0.6906 |

|

400 |

114.0025 |

4.1184 |

|

180 |

21.4816 |

0.7760 |

|

410 |

120.3246 |

4.3468 |

|

190 |

23.9833 |

0.8664 |

|

420 |

126.8507 |

4.5825 |

|

200 |

26.6345 |

0.9622 |

|

430 |

133.5943 |

4.8261 |

|

210 |

29.4353 |

1.0634 |

|

440 |

140.5554 |

5.0776 |

|

220 |

32.3856 |

1.1699 |

|

450 |

147.7613 |

5.3379 |

Waiters GPS Set Time program.

Waiters Flight Data Recorder.

Flight Data Recorder.

Recording aircraft flight data.

Aircraft Voice recorder.

Garmin GPS.

Garmin GPS Serial data Format.

Recording EFIS data.

Capture Serial data.

Convert Raw Data Files.

Free GPS Software.

Reading GPS data.

Reading Garmin GPS data.

Aircraft EFIS Flight Instruments.

Electronic Flight Instruments.

Aircraft Engine Monitor System.

Garmin G format.

Infinity landing gear LongEZ Plans Built Airplane.

Oil Heat system for Homebuilt airplane.

LongEZ Canard and main Wing.

Dynon instrument panel.

Custom Mouse cursors.

Garmin Serial Data Format.

Easy, Free Computer Time setting by GPS Receiver.

Custom mouse pointers.

Custom airplane mouse pointers.

LongEZ Nose gear doors.

Long-EZ main landing gear doors.

LongEZ grasscutter landing gear door.

Custom LongEZ mouse pointers.

Lycoming engine in LongEZ.

MT Propellor with 6 inch propellor extension.

EZNose Lift retractable nose gear for Long-EZ.

Rutan LongEZ is a plans built aircraft.

High speed homebuilt airplane.

Retractable landing gear for LongEZ.

Custom Airbus mouse cursor pointer.

Custom Velocity mouse cursor pointer.

NMEA 0183 Serial data Format.

Custom Cozy mouse cursor pointer.

Custom Aerocanard airplane mouse cursor pointer.

Custom E-Racer mouse cursor pointer.

Custom Canard airplane mouse cursor pointer.

Custom LongEZ mouse cursor pointer.

Set your Computer clock with this free GPS software.

Custom F15 mouse cursor pointer.

Custom A10 Warthog mouse cursor pointer.

LongEZ Hydraulic pump.

Retractable landing gear for a Long-EZ.

Custom F16 mouse cursor pointer.

Custom F14 mouse cursor pointer.

Custom Boeing 747 mouse cursor pointer.

Custom Boeing 767 mouse cursor pointer.

Custom Boeing 777 mouse cursor pointer.

Custom Boeing 737 mouse cursor pointer.

GPS Time Sync.

Custom Boeing 727 mouse cursor pointer.

Landing gear door rigging.

Custom Boeing 757 mouse cursor pointer.

Custom MD80 mouse cursor pointer.

Custom DC9 mouse cursor pointer.

Setting your computer to a GPS Time.

Custom RV mouse cursor pointer.

Downdraft cooling for LongEZ.

Speed brake installation.

Waiters Flight Data Recorder.

LongEZ Baggage pods installation instructions.

Waiters Custom Airplane mouse cursors.

Free GPS Time Sync Program.

LongEZ Intercom installation.

Major airframe overhaul of plans built EZ.

Weight and balance for a LongEZ.

Weight and Balance spreadsheet download for a Long-EZ.

LongEZ fuel system design.

How To remove the wings from a LongEZ.

How To remove the canard from a LongEZ.

Waiters GPS Time sync program runs on PC.

How To remove the engine from a LongEZ.

Long-EZ Downdraft cooling for a Lycoming O-320.

Long-EZ Wing Removal and installation instructions.

Waiters Retractable Landing Gear Controller.

Landing Light installation in LongEZ.

Install free EFIS software on your PC.

How to Put several longezs in one hangar.

How to install an Infinity Aerospace Retractable landing gear in a Long-EZ.

How to install DownDraft cooling on a Long-EZ.

GPS Time.

Setting you computer clock to GPS time.

How to set your Computer clock to GPS Time.

Using your GPS Receiver to set your computers clock.

Low cost GPS receiver used to syncronize Computer clock to GPS time.

Neat Canopy stay system for an EZ.

Cabin Heat using engine oil as source.

Waiters GPS Time, Syncronize your PCs internal clock with the GPS satellite.

Remote display of EFIS on a PC.

Cabin Oil Heater for a LongEZ.

LongEZ Landing Gear Door.

Rigging a LongEZ Landing Gear door.

Icom Radio in LongEZ.

How to Build a Manometer.

LongEZ Electrical system upgrades.

Grand Rapids EMS.

Custom Windows cursors.

Custom Windows mouse pointers.

LongEZ Cowling for downdraft cooling.

Record holding LongEZ flights.

Using a PLC for a retractable Landing Gear Controller in a LongEZ.

Syncronize your PCs clock to a GPS receiver.

Airspeed vs pressure lookup tables.

How to build a homebuilt airplane.

Video of LongEZ taking off.

Grasscutter landing gear door.

EZ Nose Lift installation.

Landing Gear status indicator.

Shareware software can set your PC clock vie a GPS receiver.

Landing Gear controller computer for LongEZ.

Landing gear doors.

Dynon EMS10 installed in instrument panel of a LongEZ.

Dynon EFIS D10A installed in instrument panel of a LongEZ.

Flight Data Recorder Software.

PlansBuilt LongEZ.

Video of High G turn in a Long EZ.

Strong Pitch Trim system installed in a LongEZ.

Strong Pitch Trim mounted on Left Side of Long-EZ.

Free software sets your PC clock with a GPS receiver.

Video of LongEZ Taking off.

Video of LongEZ Landing.

Video of LongEZ performing a high G turn.

Video of Infinity Landing gear being retracted into a LongEZ.

LongEZ Color White.

Painting your LongEZ.

White LongEZ.

Camoflage LongEZ.

Infinity Landing Gear for LongEZ.

Strong Pitch system.

|

Prepare 1 pint of water, preferably distilled, but soft tap water will work.

Mix food coloring into the water. Make it as dark as you can, this makes the

water level very easy to see. Mix 1 teaspoon of Dishwasher Softener into the

water. This reduces the surface tension of the water so it doesn’t stick to the

inside of the tube. Detergent will also work but you’ll have to allow the

bubbles to disperse before you can make any measurements.

Prepare 1 pint of water, preferably distilled, but soft tap water will work.

Mix food coloring into the water. Make it as dark as you can, this makes the

water level very easy to see. Mix 1 teaspoon of Dishwasher Softener into the

water. This reduces the surface tension of the water so it doesn’t stick to the

inside of the tube. Detergent will also work but you’ll have to allow the

bubbles to disperse before you can make any measurements. Blow gently into the AIR SUPPLY hose. You’ll see the water level change. Get a

feel for how much pressure it takes to move the water.

Blow gently into the AIR SUPPLY hose. You’ll see the water level change. Get a

feel for how much pressure it takes to move the water.